Introduction

Global climate change is affecting the rainfall pattern in Mauritius. The mean annual rainfall has decreased by about 8% over the last 10 years and there has been an increase in the duration of water stress periods as well. About 48% of our water resources is being used by the agricultural sector. The most common irrigation systems used for production of vegetable, fruit and flower crops are the sprinkler and the mini sprinkler. Owing to the scarcity of water for irrigation, there is a tendency to shift to the drip irrigation system which is more efficient and has a water economy of 40 to 50%.

What is drip irrigation?

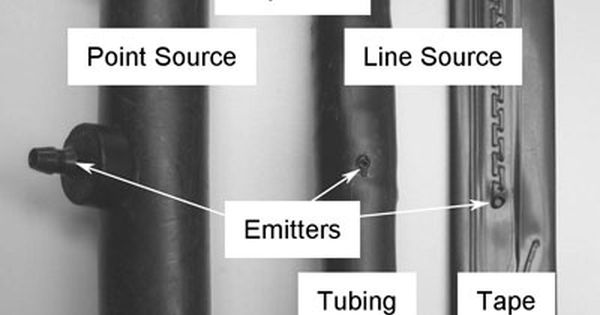

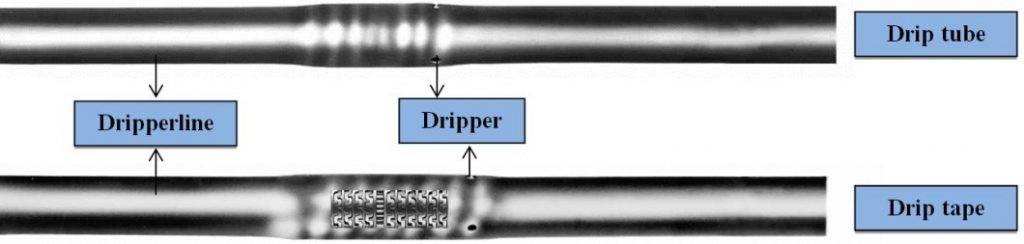

Drip irrigation is an irrigation method where the irrigation water, after passing through a filter which removes impurities, flows through a plastic tube called the dripper line laid along the plant rows. The irrigation water drips slowly near the root zone of the plant through a small hole found inside the dripper line also called a dripper or an emitter. The dripper line may be a drip tube which is tubular or a drip tape which is flat (shown below).

Drip Tube

Drip Tape

Benefits of drip irrigation

Drip irrigation offers the following advantages:

- Low pressure and low discharge (0.5 – 8.0 L/h) thus reducing energy cost

- No wastage of water. Water flows directly to the rootzone

- 40 – 50% less water utilised compared to sprinkler irrigation

- Fertilisers can be applied through the system (fertigation)

- Minimal leaching of fertilisers to aquifers

- Improved crop yield and quality

- Lower incidence of foliar diseases and weeds

- Lower labour cost

Gravity-fed drip irrigation

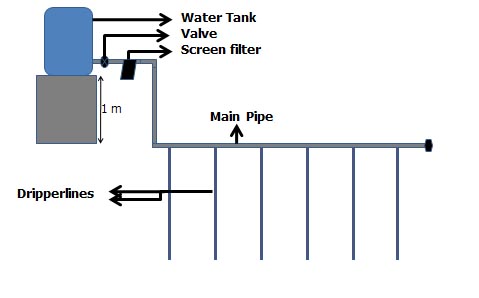

Unlike the pressurised drip irrigation system which requires an electric or petrol driven pump to pump water to the dripper lines, the gravity-fed drip irrigation requires no pump and is thus energy saving. Whenever the valve is opened, irrigation water flows by gravity through a screen filter which removes impurities, then through the main pipe to the dripper lines and drips at the root zone of the crop. The dripper lines should be closed at the end using end caps.

The first gravity-fed drip irrigation system, called the Netafim Family Drip System, was introduced by the AREU in 2002 as a means to improve foodcrop production for small-scale farming in areas where irrigation water supply is non-existent. The system currently costs Rs. 9,000.00, and it can irrigate an area of up to 500 m2.

In 2009, a larger gravity-fed drip irrigation system was introduced jointly by the AREU and the International Atomic Energy Agency (IAEA). Compared to the Family Drip System, this drip system can irrigate a larger area of up to of 1250 m2 and currently costs Rs. 30,200.00.

Components of the gravity-fed drip irrigation system

• Water tank (of a minimum capacity of 2 m3 to irrigate 1250 m2)

• 225 concrete blocks 15 cm (6”) as support (5 – 7 layers blocks giving a height of 1.2 m)

• 1 Quarter-turn valve 32 mm (1”)

• 1 Screen filter 32 mm (1”)

• 1 Elbow polypipe 32 mm (1”)

• 1 Tee polypipe 32 mm (1”)

- 50 m (2 x 25 m) Main Pipe – Polypipe 32 mm (1’’)

- 50 units Start Connector 12 mm

- 2 units End Cap polypipe 32 mm (1’’)

- Drip tape 12 mm with drippers spaced at 30 cm

- 50 End Cap polypipe 32 mm (1’’)

Distance between dripperlines: 1 m

Length of 1 dripperline: 25 m

No. of dripperlines: 50

Maintenance of gravity-fed drip irrigation system

- Daily cleaning of screen filter to prevent clogging of drippers

- Flushing of dripperlines for 2 minutes

- Every week if water used is from canals or streams

- Every month if potable water is used

- In case of severe clogging, flushing with phosphoric acid or sodium hypocholorite may be necessary. Contact your Extension Officer for advice.

- Cleaning of water tank after each crop cycle